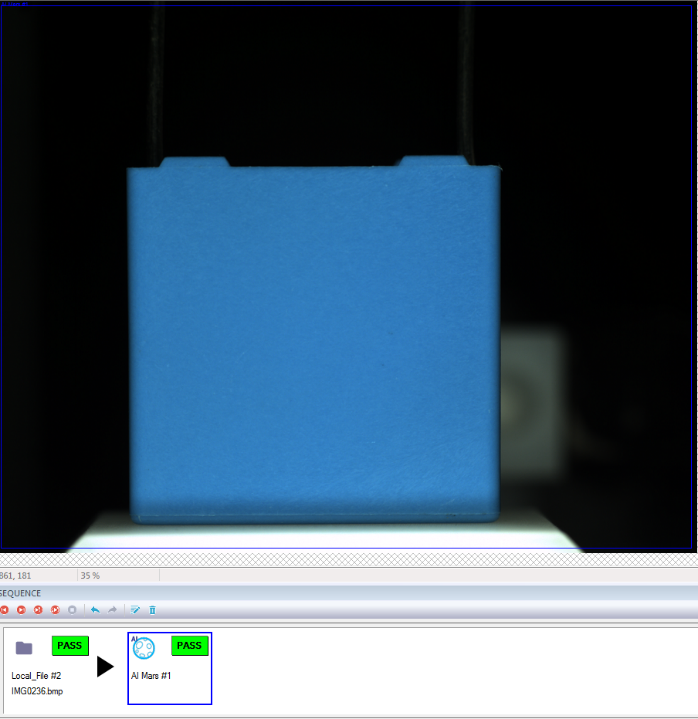

Wizer DP has 3 AI modules to meet the market needs that includes Trainer, Detect & Classify. The Trainer module is required to build up the recipe by training good selected images & different groups of NG images. The Detect module is used to detect the defects on production parts, while the Classify module classifies the defect types. It has been proven that Deep Learning can recognize a defect, even if the production parts have different variations on the threshold or machining marks.

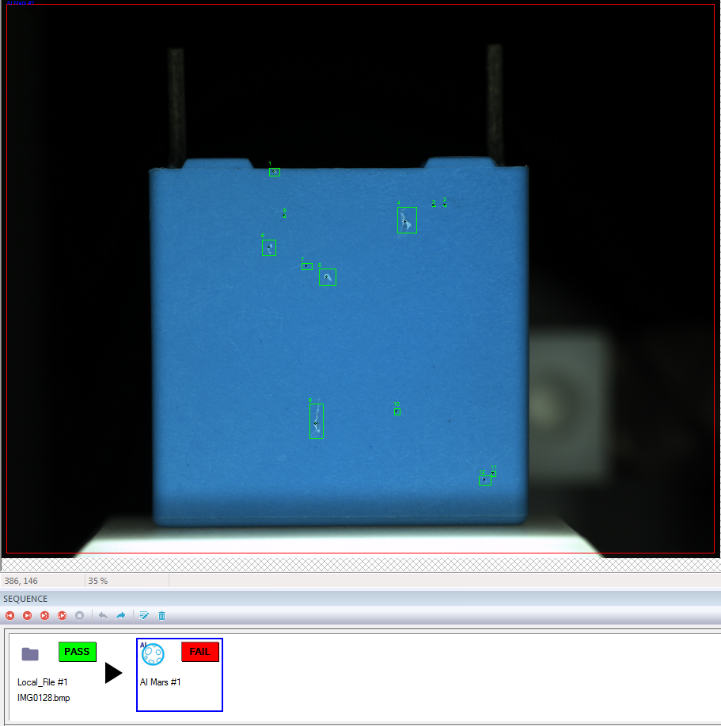

Wizer DP is able to train sufficient sample sizes of good parts, “marking” the defective areas on the NG parts. During production, new group of NG parts can be marked & added to the existing database to improve the inspection capabilities.

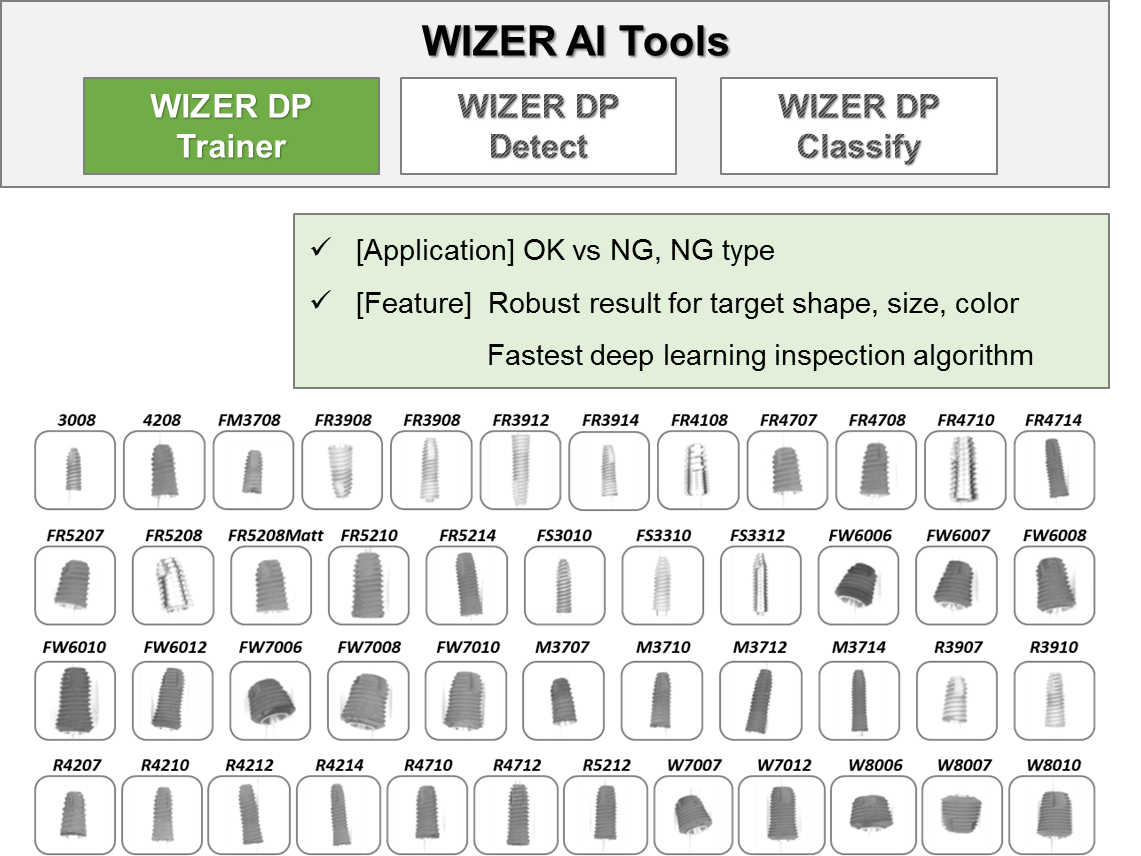

The Wizer DP Trainer Module selects good and NG images for the software to learn. Robust results include target shape, size, colour.

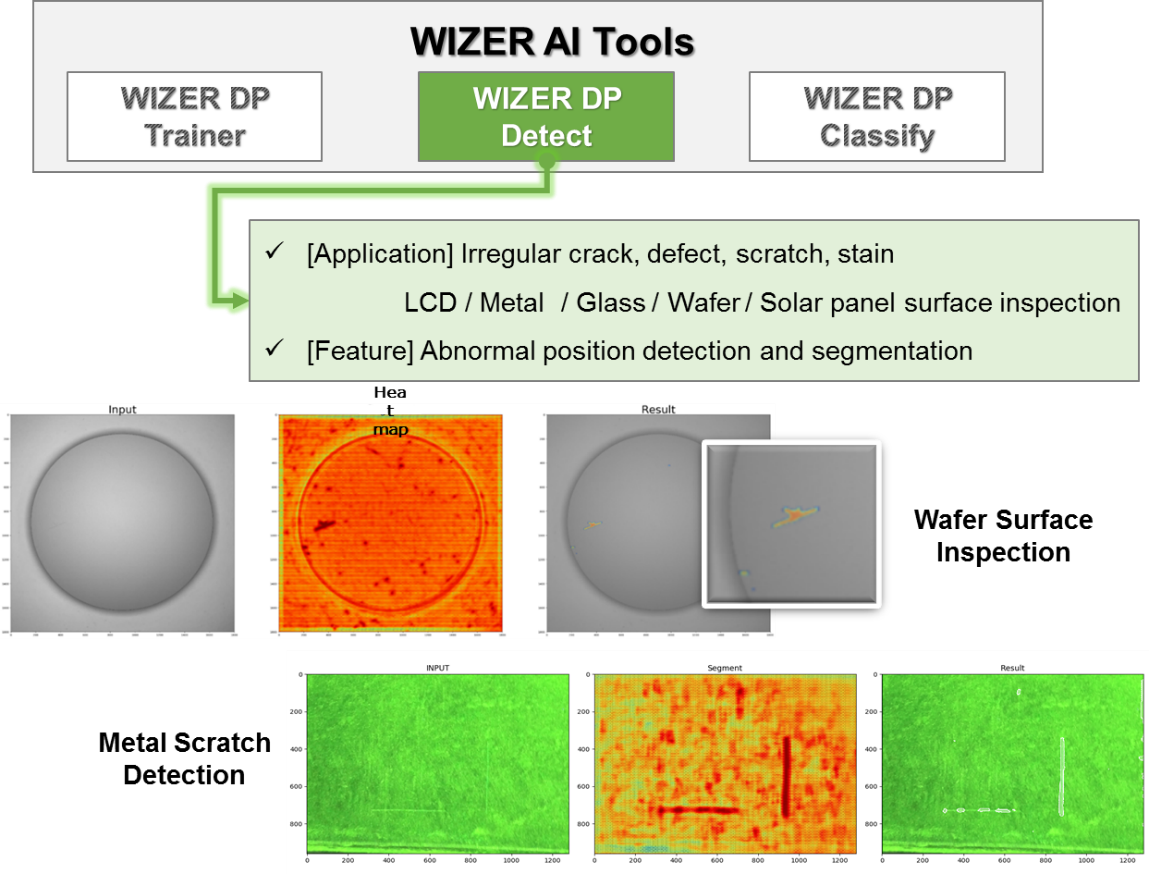

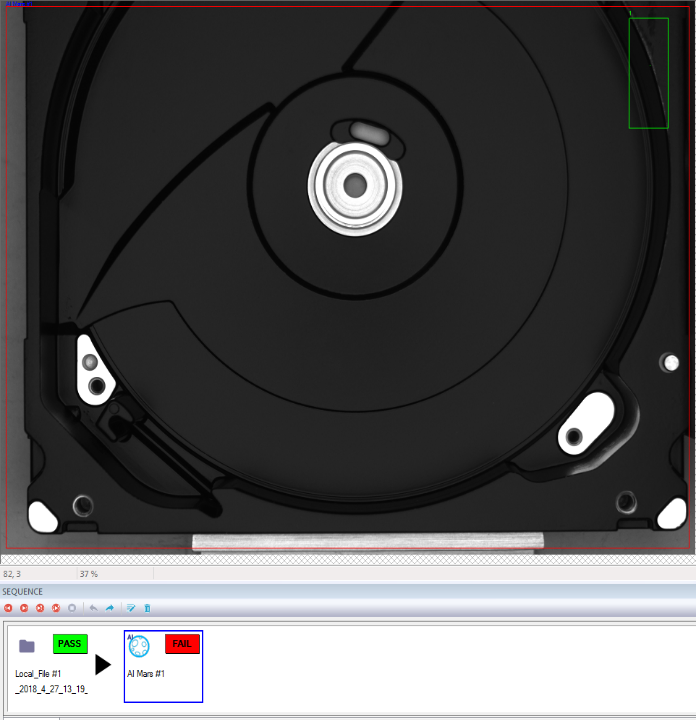

Wizer DP Detect Module detects the defects on production parts like cracks, stains or scratches. It also has Abnormal position detection and segmentation.

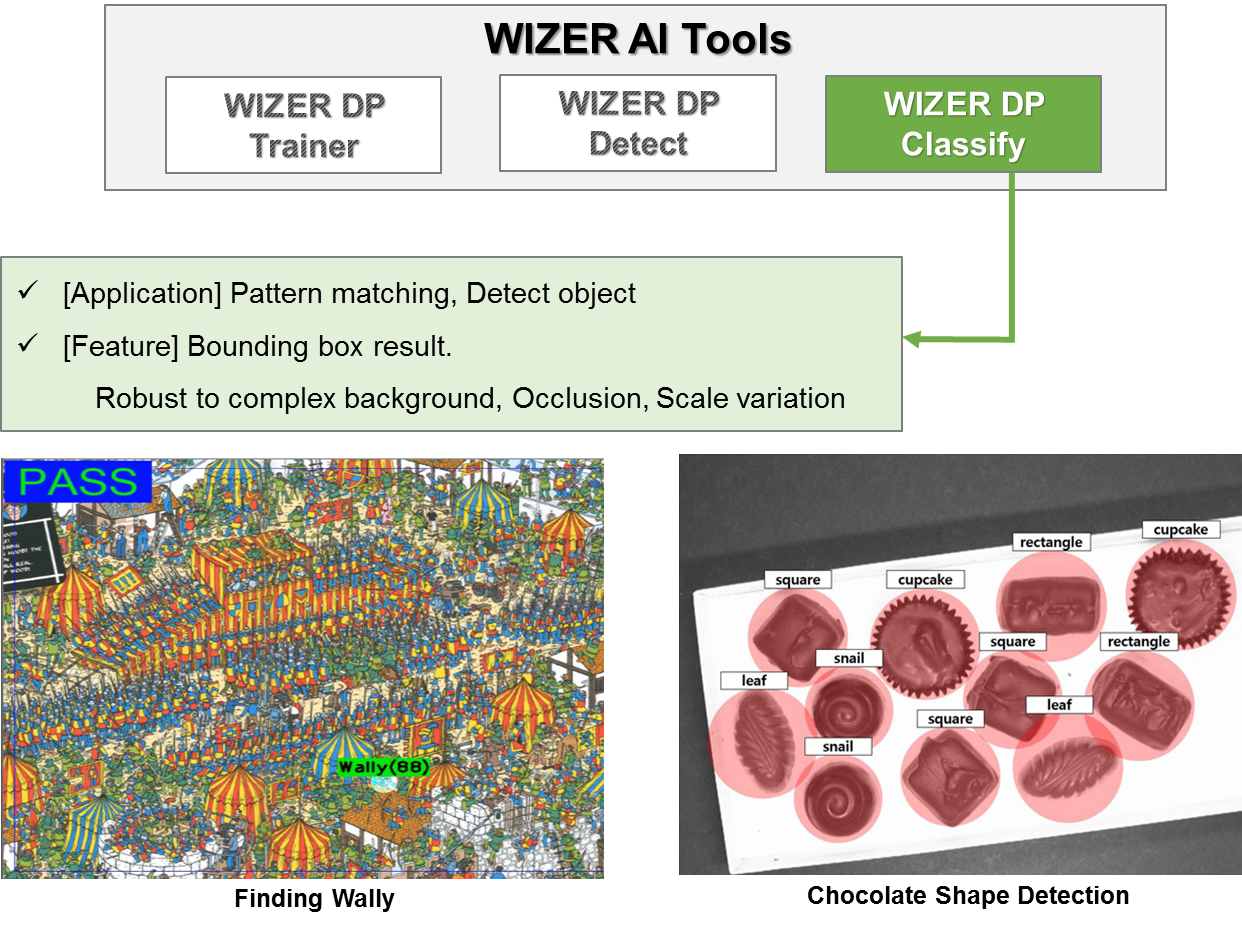

Wizer DP Classify Module classifies defect types. Robust to complex background, occlusion, scale variation etc.

You may proceed to download the datasheet now