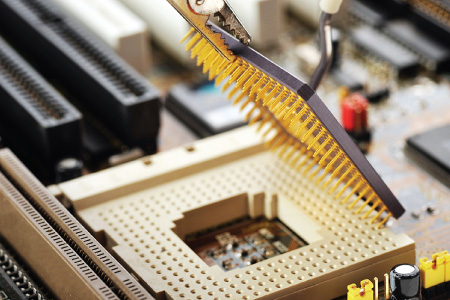

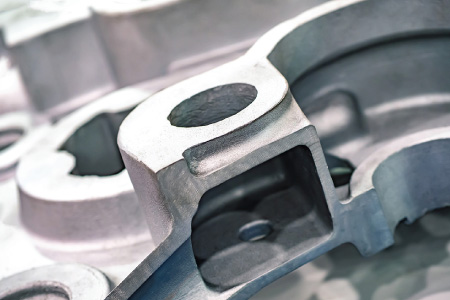

Wizer Intuit is a self-learning machine software which was developed from the hybrid of Machine Vision and AI. Utilizing its unique AI/Machine Vision approach, Wizer Intuit is able to solve complex issues during defect inspection.

The standard neural algorithm will need lots of data for improved processing. Wizer Intuit only requires a small group of good products (about 100pcs) to achieve strong results instantaneously.

As good products or images are used to lead the learning process, that significantly reduces the development time taken to create a solution when compared to traditional Machine Vision and Deep Learning approaches.

Defects Screening: After the software learning process is completed, the only adjustments needed are the strength & size tolerances.

Yield Monitoring: Many data can be collected for reporting purposes to make prompt decisions. This includes the time & period for collection, yield details, warning, etc.

Illumination & Program Control: The digital control of the illumination can be managed for different projects or product type. This will allow auto changes for light intensity.

Wizer Intuit provides a viable solution for defect inspection for applications to meet its design rules. With traditional Machine Vision, the inspection capabilities can potentially be enhanced even further.

You may proceed to download the datasheet now